|

| Copper Autumn Mums Earrings by Cindi McGee |

Materials:

Makin’s Clay® - White (or any scrap colors)

Makin’s Professional® Professional Clay Tools - Sphere tool

Makin’s® Clay Tool Set

Makin’s® Clay Roller

Makin’® Circle Clay Cutter Set

Beacon Mixed-Media Glue®

DecoArt® Dazzling Metallics® - Copper

Fine paintbrush

Bronze/Copper French earring wires, jump rings, eye pins

Copper toned crystal beads

Jewelry pliers

Instructions:

I save “extra” Makin’s Clay® from my projects for use in future projects. As long as you store it in an airtight container, such as a zipper bag, with a damp paper towel or moist towelette, the clay will remain fresh for later use. For this project, I actually used some of that scrap clay - I have one bag that is small bits of assorted colors - so please disregard the fact that the clay I used appears “dirty.” The finished earrings are painted so it does not really matter what color your base clay is. The flexible and lightweight nature of Makin’s Clay® when it is dry makes it ideal for delicate projects like this, as the petals will bend a bit rather than be fragile and break off easily.

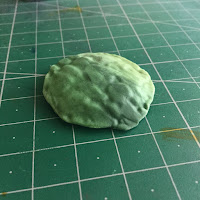

Roll clay into two balls about 3/4”, flatten the balls. It is okay if they are irregular.

Roll a strand of clay about 1/8” in diameter (Optional: Use the Makin’s Professional® Ultimate Clay Extruder® and single hole disc #2 or #3 to extrude a strand for this step.)

Use tool to cut pieces about 1/4” from the strand. Take your fingertip and gently roll the pieces to a point on one end to create petals.

Place the flat edge of the tool onto the petals to create an indentation from the point to the end.

Place the first row of petals onto the disc, using the sphere tool to gently push the ends against the disc.

Repeat with a second layer, alterating placement of the petals. Then, repeat with additional layers as desired, using less petals each time, bringing them in closer and closer toward the center as you go until your mum is fully formed.

Let dry 24 hours.

Roll clay to about 1/8”. Use circle cutter large enough to cover the base area of each mum.

Assemble French earring wires, adding a crystal on an eye pin, and then a small jump ring to each. Trim 2 more eye pins to about 1/2”. Attach the earring wires. Place the pins against the back of each earring. Add a touch of Mixed-Media Glue and place the cut circles over the pins, pressing into place to adhere and secure the pins.

Let dry 24 hours.

Paint each mum with Dazzling Metallics copper paint.